COVID-19's Effects of Supply Chain

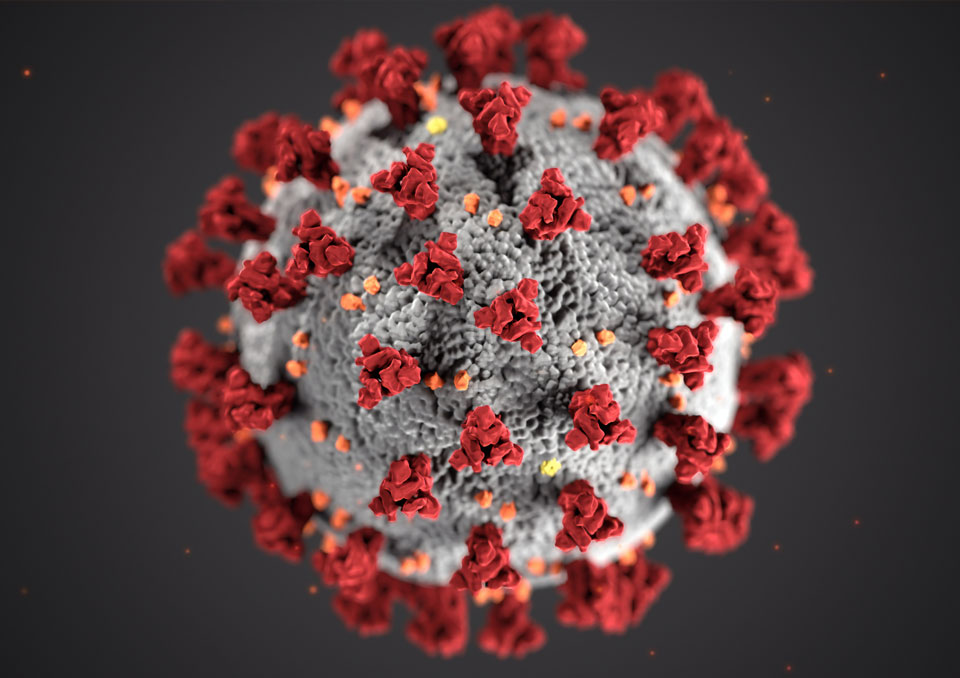

As you have certainly heard, the coronavirus that causes COVID-19 has wreaked havoc on the world economy, while thousands have died or lost loved ones to the virus. The effects of COVID-19 are being powerfully felt now in America. Most of us, for instance, have likely experienced the direct effects of supplier disruptions at our local grocery stores. The effects on trade continue to ripple and magnify as the virus spreads to all parts of the world. Semco is positioned in an industry that has already experienced serious supply chain disruptions well before COVID-19 overtook parts of Wuhan Province in China. We have detailed in this blog the causes of those disruptions in the past few years, mostly due to the trade war between China and the US that began not long after President Trump took office. Our experiences dealing with these disruptions in the supply of raw materials and various graphite grades taught us a lot about ensuring a dependable supply of material for our clients’ graphite manufacturing needs. Semco Carbon has been proactive: we regularly stock in our warehouse over 300 tons of quality material from sources across the world. This stocking of material, plus our ability to produce our own graphite formulations in house, allows us to provide quality product to our regular customers with no interruptions. COVID-19 presents a new challenge for us, an unprecedented one that we nevertheless feel equipped to manage so that our customers experience as few disruptions to their businesses as possible.

Disruptions Ahead

Though Semco has invested much in material availability and feel we are positioned well with regards to raw material availability, COVID-19 has created disruptions in the supply chain on a scale never seen before. Some common graphite grades come to the US primarily from China, so we are confident in our assessment that some disruptions to the supply of graphite are inevitable.

While it is well known that China produces and distributes many graphite grades, what is not as well known is that the raw materials used in the manufacture of graphite here in the US are frequently sourced from China. The two main ingredients in synthetic graphite are petroleum coke and coal tar pitch, both of which are heavily imported from China. Although we do not yet see large-scale shortages of these two materials, we are quite sure that the disruptions in the supplier chains will eventually reach these materials and our industry in turn. A shortage in synthetic graphite in the near future is probable, if not assured. What is not as clear is how long that shortage will persist. This, of course, depends on another unknown: how long the COVID-19 pandemic lasts. It is possible that the effects on US graphite manufacturing will be mild, and it is possible the effects will be severe.

Semco is Here

Semco advises our customers to analyze the road ahead using up-to-date data. If these analyses lead to concern, we urge our customers to reach out to us and describe the outlook on their graphite needs. We appreciate our customers reaching out in the past about the effects of supply-chain disruptions. These communications help guide and inspire our mission to support our customers in any way possible. We are here and we are ready to do our part to keep our clients’ businesses running.