Shipping Costs in Graphite Manufacturing

To ensure a reliable supply of material for our graphite manufacturing operation, we are always searching for qualified raw material vendors. In recent years, new overseas vendors have become competitive by developing excellent track records for material quality. To offer reliable graphite fabrication to our clients, we rely on vendors who we know will deliver excellent raw material. We have, therefore, cultivated relationships not only with domestic vendors, but also with some of these international vendors, especially ones based in China. By 2019, Semco achieved in our raw material purchases a healthy balance between domestic and import vendors.

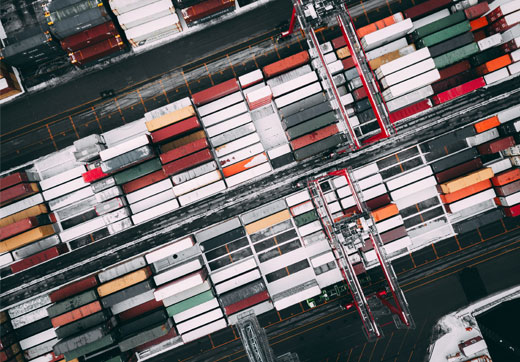

Working with international vendors, despite its benefits to our graphite manufacturing operation, does come with some wild cards. One of those unpredictable aspects of importing raw graphite from, say, China, has always been shipping costs. Normally, import material comes into the US in large shipping containers, delivered over the seas on large container ships. The ebbs and flows of the pricing of this kind of shipping meant slight adjustments in material cost for imported materials.

And then came 2020 and COVID. The pandemic has impacted almost all industries in ways big and small. For our graphite fabrication business, the pandemic had a huge impact on shipping costs.

Historically, a fully loaded container coming from China to us cost somewhere in the $1,800 range. In the early months of the pandemic, after much of China had been on lockdown for a while due to COVID, the cost of shipping one container rose to approximately double the original amount. Getting a container fully loaded with raw graphite materials to our graphite manufacturing facility in Ohio suddenly cost roughly $3,600. Then, things got even more complicated.

What happened in the last 12 months is almost unbelievable. With the flow of products mainly going in one direction, from China to US, an unexpected consequence happened: containers that used to go back and forth between China and the US were suddenly stuck in US ports. There was little to ship back to China, and shipping companies balked at wasting voyages across the Pacific Ocean just to deliver empty shipping containers. Coupled with high demand for imported goods in the US, and a significant rise in the price of fuel, the last 12 months saw the cost of shipping per container go from $3,600, to $5,000, to $6,000, then to $10,000. In one staggering instance, we were recently quoted $22,000 to ship one container. Needless to say, at that price, the shipping costs exceed the value of the product inside.

A rearrangement was clearly necessary for our business to continue offering affordable prices for graphite fabrication. Although we maintain a healthy relationship with some of our traditional import vendors, it only made sense to reorient and place more orders with our domestic raw material manufacturers.

No one in the graphite manufacturing industry saw this development coming. But now, due to the COVID pandemic and the subsequent upheavals in the global supply chain, domestic producers of raw graphite material are not only more competitive in our field, but they are more competitive by a wide margin.

Challenging times call for tough, smart decisions. Our strong relationships with well-established domestic vendors has provided us with the flexibility required to continue producing quality graphite product for our customers with no downtime.